About Me

Controls Engineer with expertise in mechatronics, bridging mechanical systems, electronics, controls, and software to support reliable automation.

Based out of Yorktown Heights, New York, I received my B.S. in Mechanical Engineering from Rensselaer Polytechnic Institute (RPI) in Troy, NY. I continued my education at RPI and specialized in control systems. As a graduate research assistant, I worked on a team focused on developing hybrid manufacturing, using two robots to demonstrate additive and subtractive manufacturing with metal parts. This system consisted of one repurposed welding robot that would deposit metal wire, while the spindle robot would machine the metal to smooth out the surface.

After receiving my Masters of Engineering in Mechanical Engineering, I began working at Sikorsky, a Lockheed Martin Company in Stratford, CT. There I worked on electrical builds and installs on aircraft, including MH-60R Naval Hawk and developmental FARA aircraft. I contributed to an automation project that placed electrical pins into connectors subsequently used on aircraft. Additionally, I guided electrical routing paths and electrical equipment installs on the developmental FARA aircraft.

I currently work at eMagin, a Samsung Display Company in Hopewell Junction, New York. Here, I led the qualification process for an adhesive dispensing and glass lens placement tool. I have also lead yield improvement efforts, developed a custom consumable estimator, and routinely trouble shoot equipment issues.

Take a look at some of my hobby projects below that showcase my mechanical design, controls, electronics, and software programming skills.

Education

Rensselaer Polytechnic Institute

M.Eng. in Mechanical Engineering - Control Systems (2022)

B.S. in Mechanical Engineering (2021)

Certifications

FAA Part 107

sUAS Commercial Drone Pilot

Projects

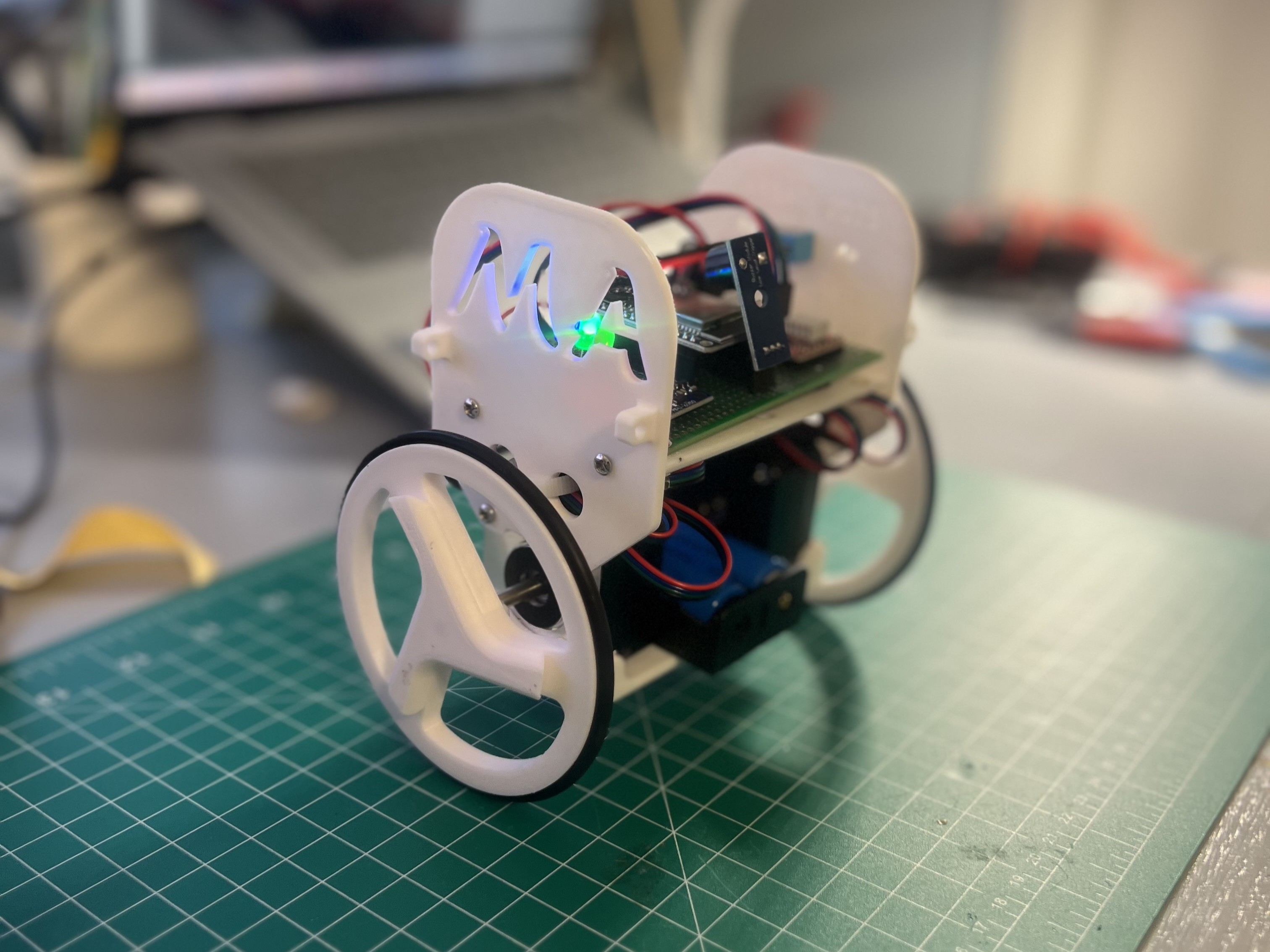

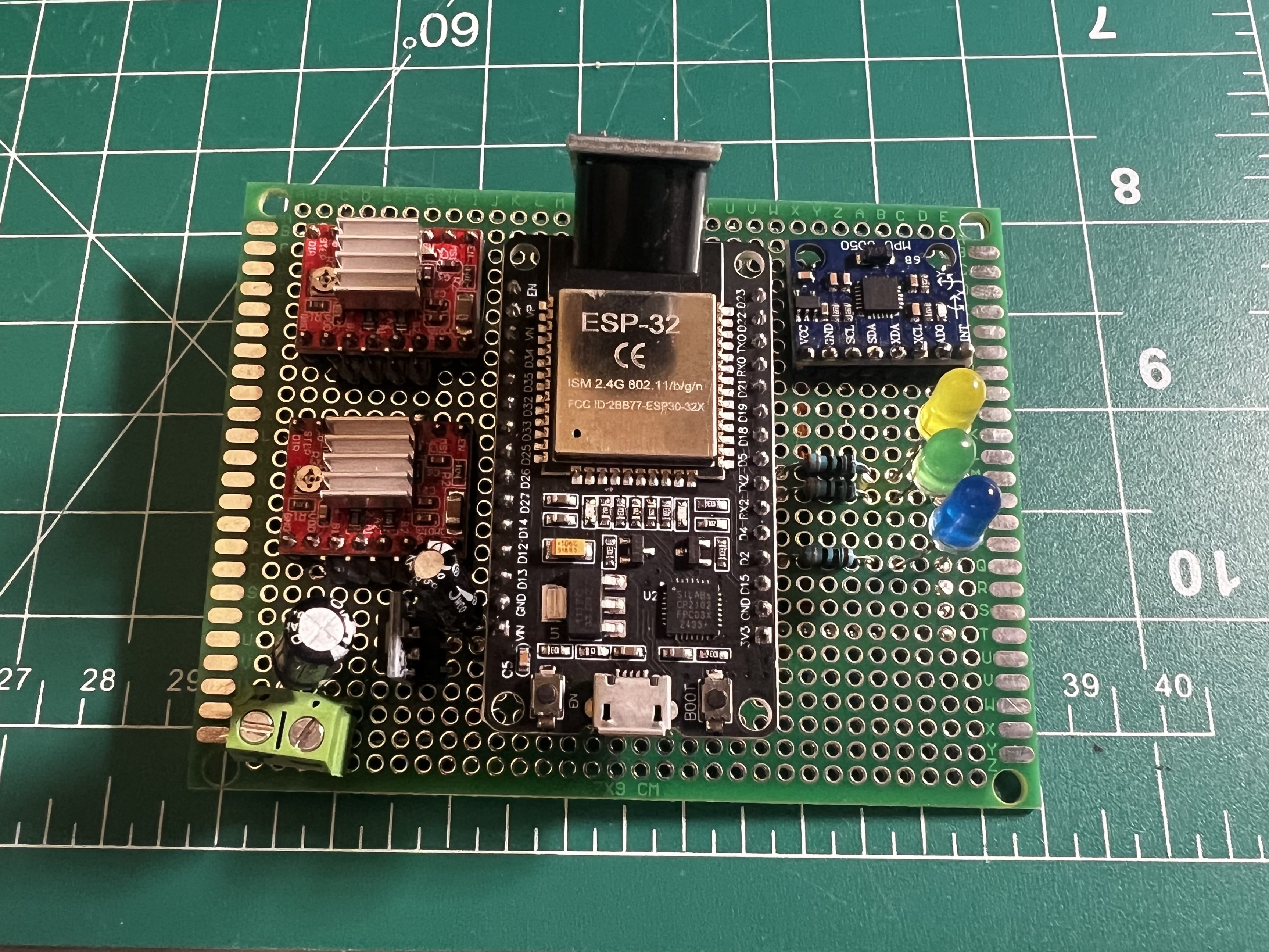

ESP-32 Balancing Robot

❮

❯

❮

❯

This is a self-balancing robot built on the ESP32 microcontroller, using an MPU6050 IMU for tilt sensing, 2 NEMA 17 stepper motors, 2 A4988 motor drivers, blue,yellow and green LED indicators, and a piezo buzzer for sound.

The Control System

I used a cascaded PID to control this robot. The outer PI loop handles the velocity while the inner PD loop keeps it balanced. The MPU6050 IMU outputs acceleration and gyroscope date. From this, it can detect the angle of lean and drive the motors to counter-act this lean at 100 Hz.

Wireless PS4 Control

For steering, I am using a PS4 controller connected via the Bluepad32 library. The left stick controls the throttle and the X axis handles the steering. I also added some adaptive filtering and speed dependent gains to increase stability at higher speeds.

MPU6050 Filtering

This system uses a complementary filter for the angle measurements. The weighting is 99% gyroscope 1% accelerometer. Accuracy is within 0.2 degrees.

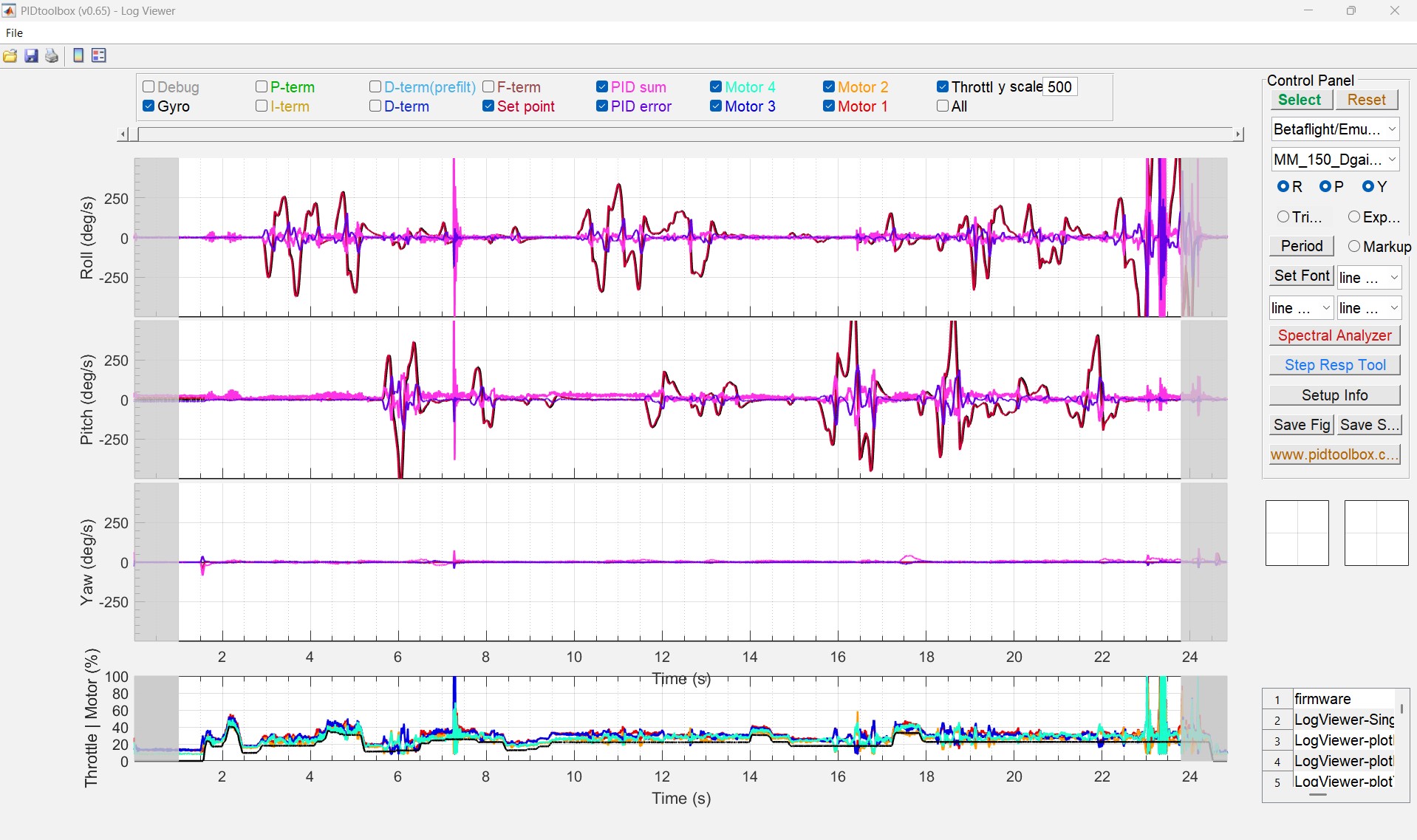

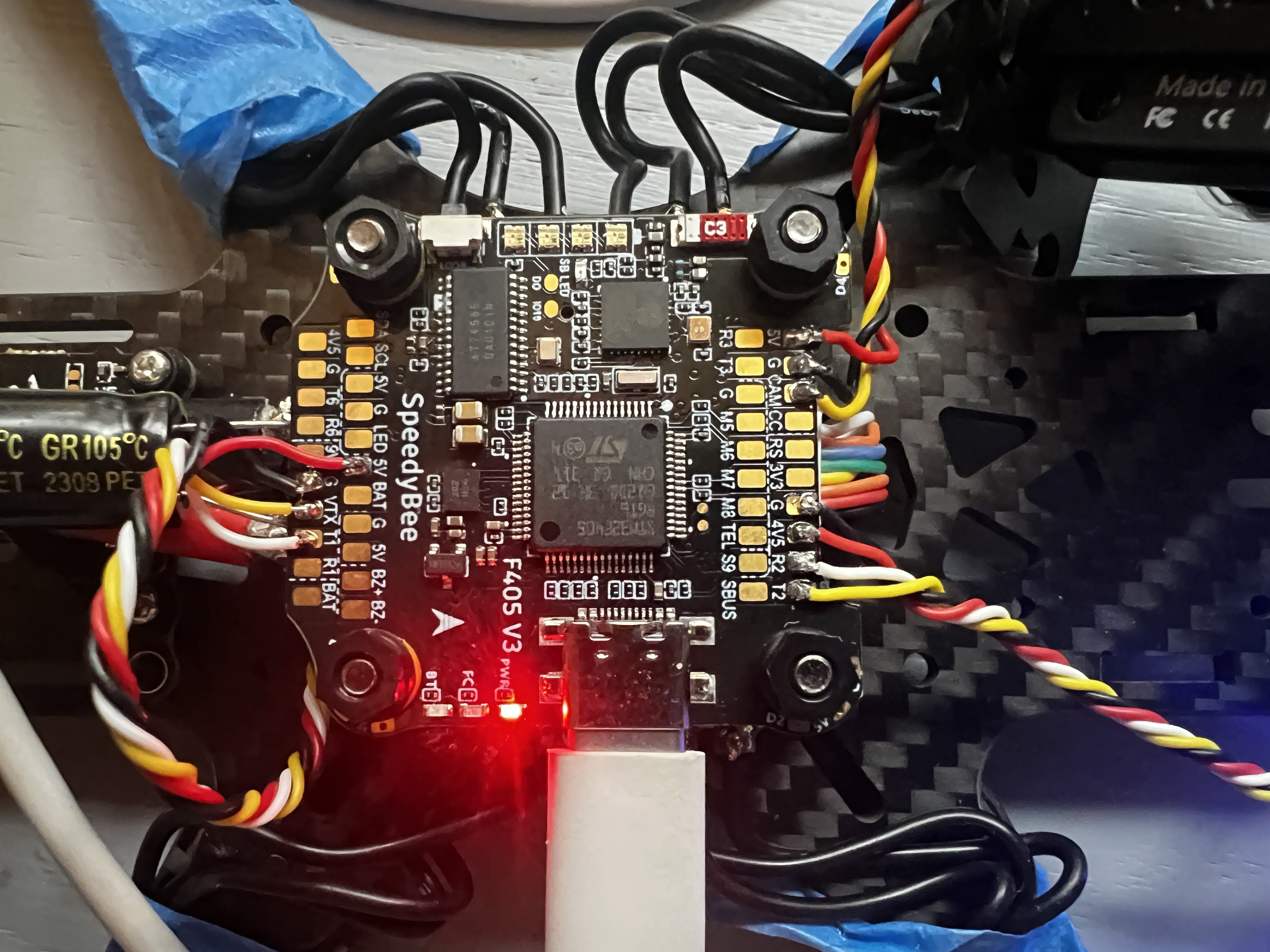

Quadcopter Drone Build

❮

❯

❮

❯

This project demonstrates a high-performance FPV (first person view) quadcopter, from electrical assembly and to the controls tuning. Some aspects tuned included the PID gains via recorded flight data, designing filters to filter out resonance vibrations, and using feedforward input.

Electrical Assembly

Soldered a 4-in-1 Electronic Speed Controller (ESC) to brushless DC motors, ensuring clean signal paths.

System Configuration

Configured the Betaflight flight controller firmware, including motor resource remapping, ELRS radio communication and FPV video system.

PID Tuning

Performed field-tuning of the PID controller to eliminate prop-wash oscillations and achieve high responsiveness.

Flight Data Analysis

Implemented Blackbox data logging to analyze flight performance and fine-tune dynamic notch filters for motor noise reduction.

Contact Me

Email: matthew.c.abbate@gmail.com